Our products and services

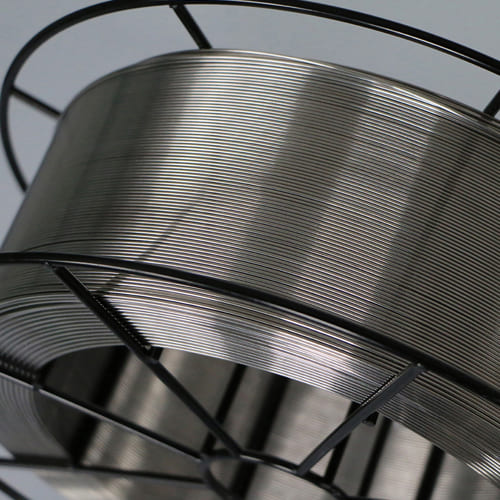

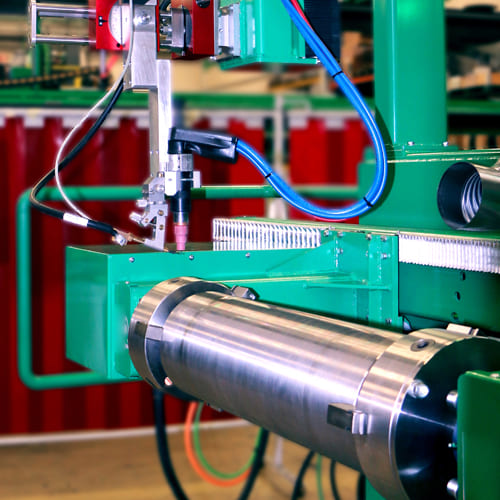

For more than 50 years, industrial users across the globe have relied on the expertise of Welding Alloys to increase productivity and reduce costs through our extensive range of welding consumables, automated welding equipment and engineered wear products and services. Click on a product or service below to find out more.