Sugar

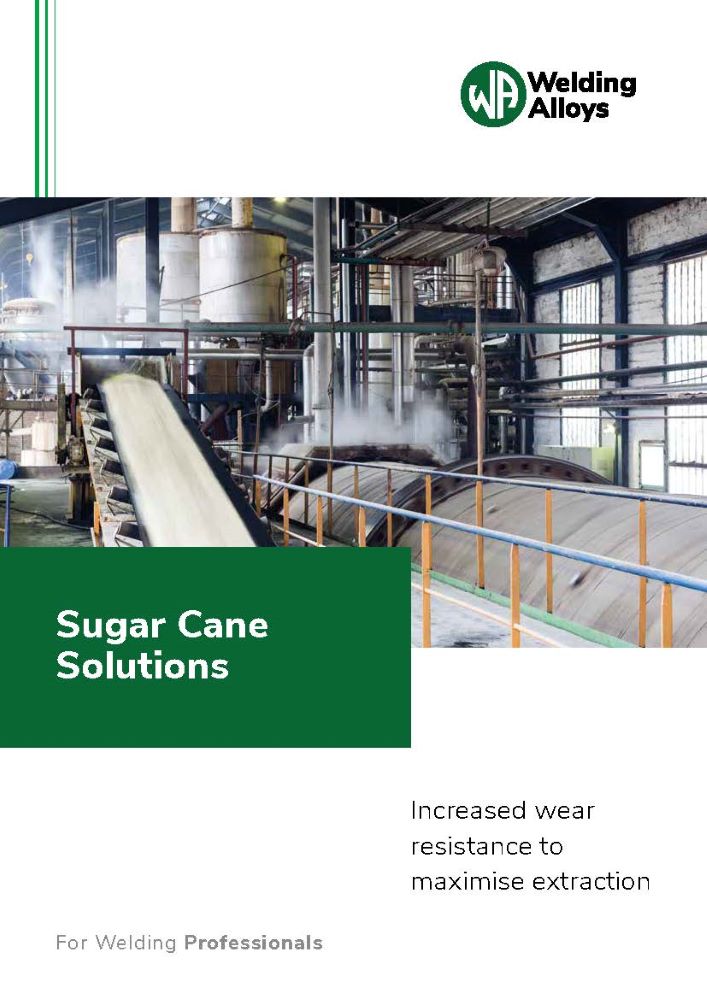

At Welding Alloys, we offer a wide range of products, services, and equipment to solve wear problems that occur in the sugar industry. Our industry knowledge and expertise mean we can increase the lifespan and productivity of sugar rolls, crop dividers, shredders, knives, and chopper rollers used in the sugar cane industry, anywhere in the world.

To combat the effects of abrasive and corrosive wear of equipment used in sugar mills, we use Welding Alloys cored wires specially developed for hardfacing, building up of the rolls and of other machinery, back to the original profiles. Through our strategically located Integra™ Service Centres, we can provide wear audits and technical support across the world.

At Welding Alloys, we can successfully protect and improve the wear resistance of fan impellers and casings across various industries. We offer standard and customised solutions for fans, fan blades, fan casings, and related equipment to protect against wear caused by factors such as corrosion, abrasion and erosion.

Our 3D-Carb™ technology achieves a 30% increase of lifetime, when compared with industry standard equipment.

Shedders can be exposed to various materials that cause wear and abrasion. Our extensive range of welding consumables, complemented by a comprehensive range of wear plates, can extend the lifetime of the component.

Our technical engineers use our trusted Welding Alloys welding equipment to repair, refurbish, and apply arc spatter to sugar mill rollers, resulting in many years of optimum cane crushing.